Comprehensive Maintenance Guide for Glass Machinery

Body: Glass machinery is an indispensable piece of equipment in the glass processing process, and its performance and precision directly affect the quality of glass products. To ensure the normal operation of the equipment and extend its service life, correct maintenance is crucial. Here is a comprehensive maintenance guide for glass machinery:

I. Daily Maintenance

1. Cleaning: At the end of each workday, wipe the surface of the glass machinery with a clean

cloth or sponge dampened with clear water to remove dust and dirt. For stubborn stains, use a

neutral detergent or special cleaning agent to gently scrub, avoiding cleaners with acidic or alkaline

components to prevent corrosion of glass and mechanical parts.

2. Lubrication: Regularly lubricate the transmission system, bearings, gears, and other parts of the

glass machinery to reduce wear and extend the life of the parts. Use the appropriate lubricating oil

and lubricate according to the recommendations of the equipment manufacturer.

3. Inspection: Before each use, inspect various parts of the glass machinery for normalcy, including

fasteners, transmission parts, electrical systems, etc., ensuring there are no signs of loosening or

damage.

II. Regular Maintenance

1. Maintenance of Lubrication System: Regularly check the quality and oil level of lubricating oil, and

replace it with new oil when necessary. Pay special attention to parts that require lubrication, such as

gearboxes and bearings.

2. Maintenance of Water System: Regularly replace circulating water, clean the water tank and filter

to prevent the buildup of scale and contaminants, which can affect the performance of the equipment.

3. Inspection of Electrical System: Check for wear, aging, or damage to cables, terminal connectors, and

electrical components, and replace or repair them when necessary.

III. Seasonal Maintenance

1. Adaptation to Temperature Changes: During seasonal transitions, especially when there are large

temperature fluctuations, pay special attention to the adaptability of the equipment. For example, in

winter, prevent equipment from damage due to extreme temperature differences that could lead to

glass breakage.

2. Anti-freezing Measures: In cold regions, take appropriate anti-freezing measures, such as using

antifreeze and insulating materials, to protect the glass machinery from the effects of low temperatures.

IV. Maintenance of Special Parts

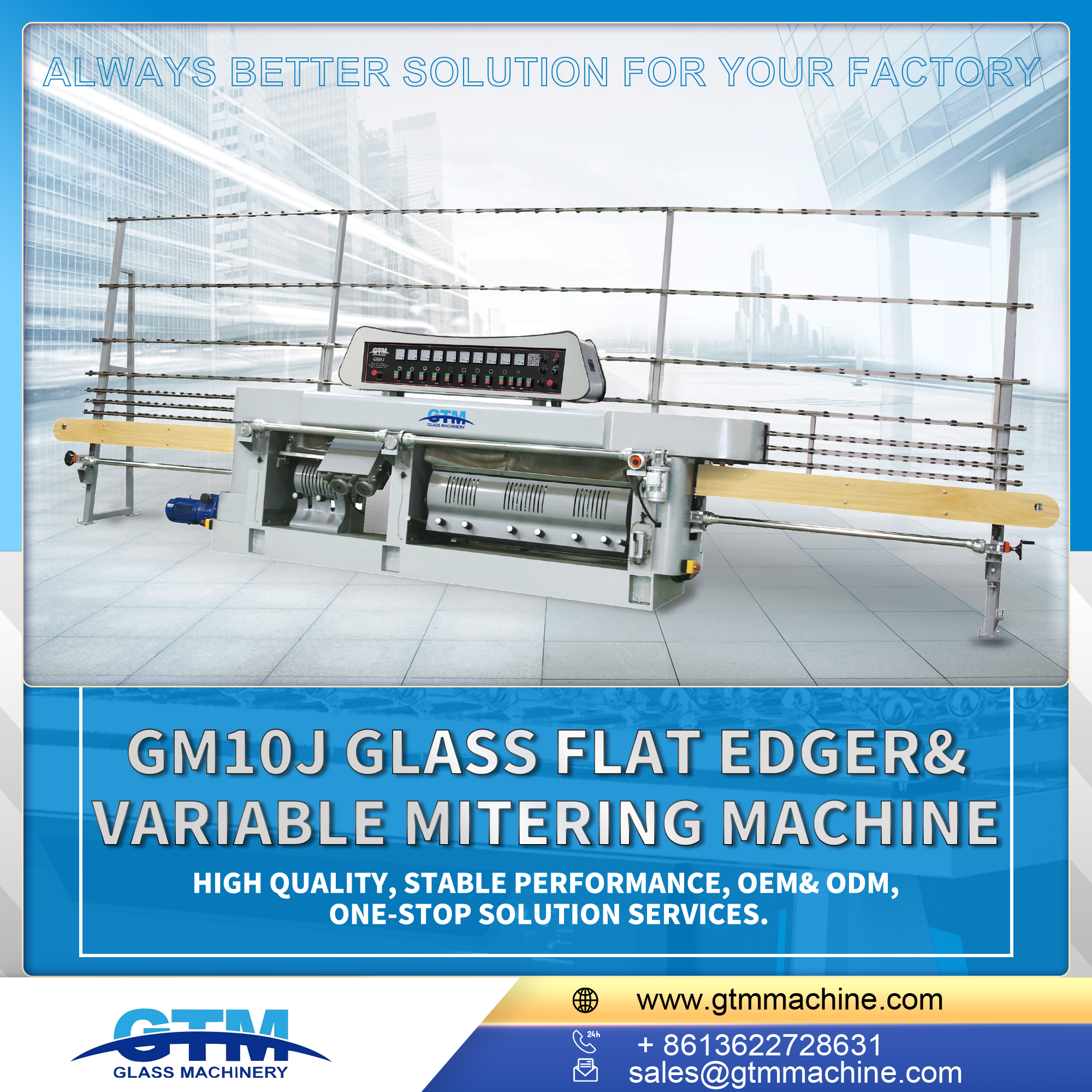

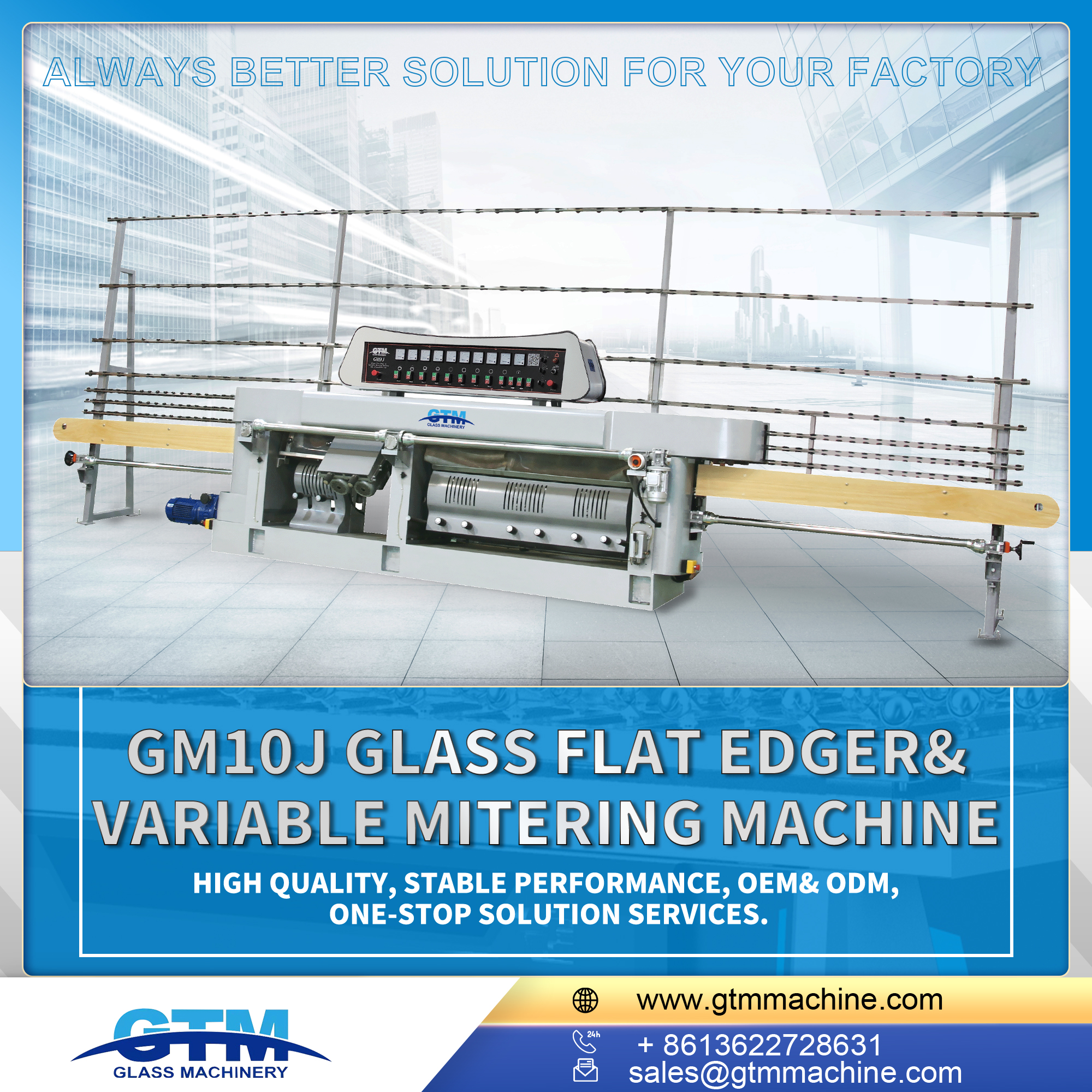

1. Maintenance of Edge Grinding Machine: In addition to daily cleaning and lubrication, regularly

check the wear condition of the grinding wheel, and replace or dress the grinding wheel in time to

ensure the quality of grinding.

2. Maintenance of Glass Washing Machine: The maintenance of the glass washing machine includes

regularly cleaning the water tank and receiving water tray to ensure water cleanliness, as well as

inspecting and adjusting the cleanliness and angle of the air knife drying area to ensure the drying

effect.

V. Fault Prevention

1. Regular Inspection: Regular inspections can identify and resolve potential issues, preventing minor

problems from becoming major failures.

2. Operator Training: Ensure that operators receive proper training to understand the operating

methods and daily maintenance knowledge of the equipment to reduce damage caused by improper

operation.

Conclusion: The maintenance of glass machinery is a systematic process that involves daily

maintenance, regular maintenance, seasonal maintenance, and the maintenance of special parts. By

following the above maintenance guide, you can effectively improve the work efficiency of the

equipment, extend the service life of the equipment, and ensure the quality of the processed glass

products. Regular maintenance and care are key to ensuring the normal operation of glass machinery.