GTM Glass Machinery's environmental advantages

In the context of today's increasing environmental awareness, the glass machinery industry is also

continuously pursuing technological innovation and breakthroughs to achieve more environmentally

friendly production methods. As a leader in the industry, GTM Glass Machinery's environmental

advantages are mainly reflected in the following areas:

1. Application of Energy-saving Technology: GTM Glass Machinery adopts advanced energy-saving

technologies to reduce energy consumption and production costs by optimizing equipment design

and process workflows. For example, frequency conversion drive technology is used to reduce motor

energy consumption, and waste heat recovery systems are utilized to improve energy utilization rates.

2. Reduction of Waste Emission: GTM Glass Machinery focuses on reducing the generation and emission

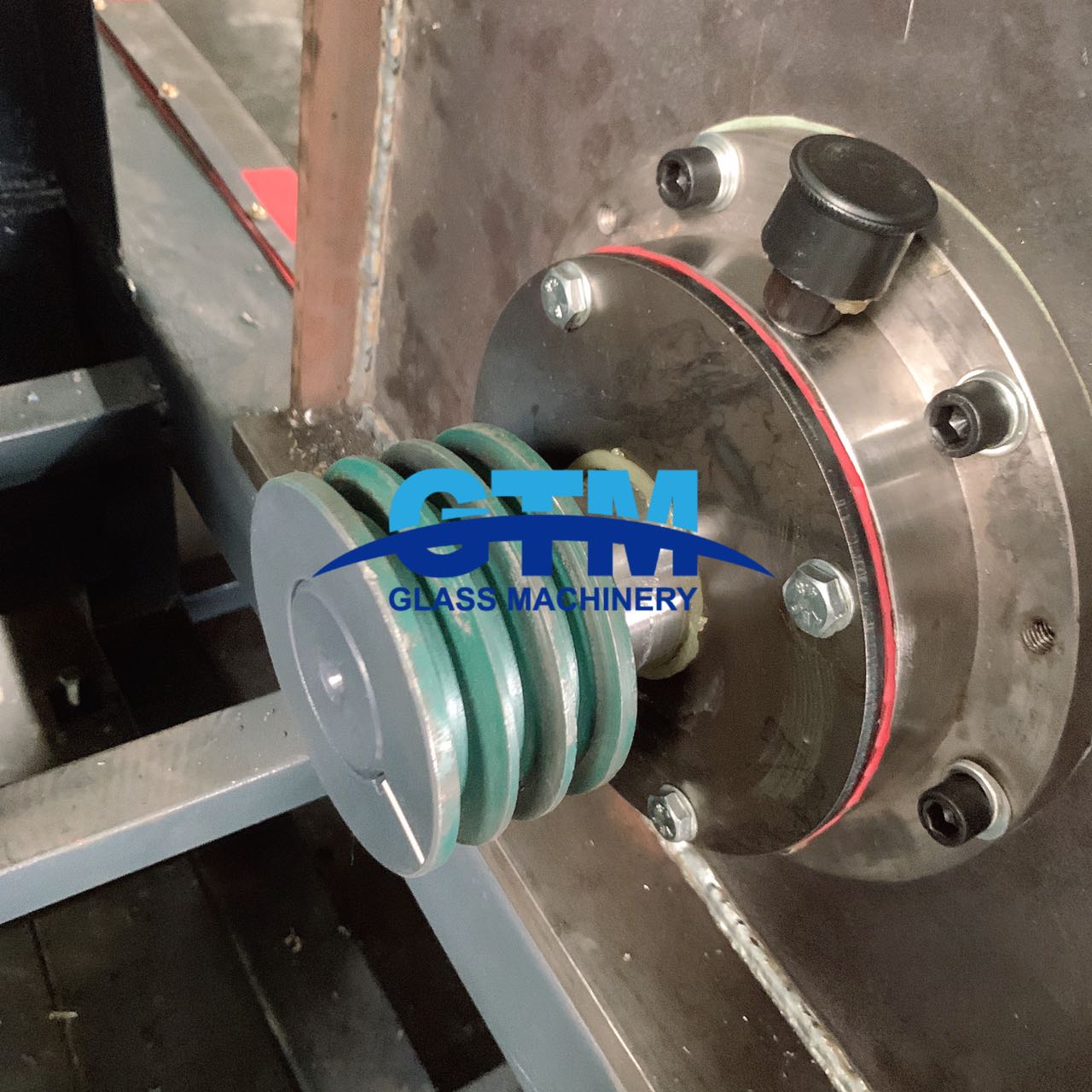

of waste during the production process. By improving production technologies, such as using

enclosed

edge grinding techniques to reduce the creation of glass dust, and recycling the waste generated

during production, the impact on the environment is minimized.

3. Low Noise Design: In the design of glass machinery, GTM pays attention to reducing the noise level

of the equipment. Measures such as using soundproof materials and optimizing mechanical structures

are taken to reduce noise pollution during the production process and provide a healthier working

environment for operators.

4. Clean Production: GTM Glass Machinery promotes the concept of clean production. By adopting

water circulation systems, dust collection systems, etc., it reduces the emission of wastewater and dust

during the production process, achieving a cleaner production process.

5. Use of Environmentally Friendly Materials: In the manufacturing process of equipment, GTM Glass

Machinery prioritizes the selection of environmentally friendly materials, such as using recyclable metal

materials and coatings with low volatile organic compounds (VOC), to reduce environmental pollution.

6. Intelligent Control Systems: GTM Glass Machinery is equipped with intelligent control systems that

achieve precise control of the production process, reduce the waste of raw materials, and improve the

finished product rate, thereby reducing resource consumption and the generation of waste.

7. Green Supply Chain Management: GTM Glass Machinery focuses on establishing a green supply

chain, collaborating with suppliers to prioritize environmentally friendly materials and energy-saving

products, ensuring the environmental performance of the products from the source.

8. Product Life Cycle Assessment: GTM Glass Machinery conducts life cycle assessments of its products

to ensure that the equipment meets environmental requirements at every stage of design,

manufacturing, use, and disposal, reducing the impact on the environment.

Through the above measures, GTM Glass Machinery not only improves production efficiency and

product quality but also makes a positive contribution to the sustainable development of the glass

processing industry. With the continuous advancement of technology and the increasing demands of

environmental protection, GTM Glass Machinery will continue to commit to the research and

application of environmental protection technologies, leading the industry towards a greener future.