Regarding the operation process and precautions of the glass drilling machine

Regarding the operation process and precautions of the glass drilling machine

Many people think that the drilling machine is only divided into engineering drilling machines and

items drilling, but we don't know that the glass also has a special drilling machine. Let's talk about the

operation and precautions of the glass drilling machine today.

What is a glass drilling machine?

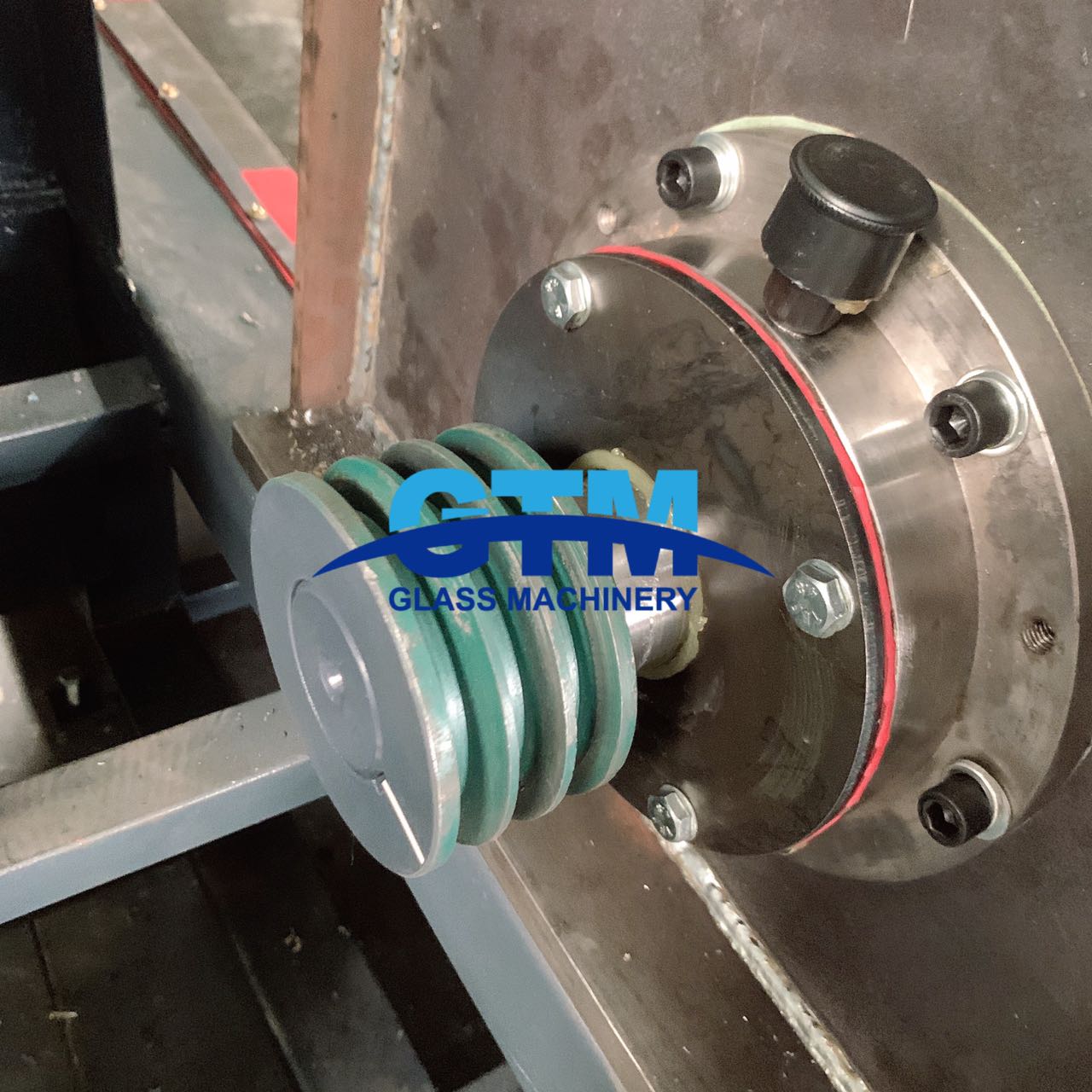

Glass drilling machine is a machine specially used for glass drilling. It is mainly divided into: base,

operating table, drill bit, motor, etc. The diameter of the drilling hole is large, the machine seat

suspension is large, and the drilling holes of the glass of a variety of sizes can be drilled.Working table,

the workbench is low, the operation is convenient, the lower drill head uses air pressure adjustment,

and the speed is stable. It is the ideal drilling machinery of glass processing enterprises.

Precautions

1. Pay attention to safety when debugging and using glass drilling machines. Do not touch the

movement and power parts when the machine starts;

2. Do not put the tools and other objects on the conveyor rail and cover;

3. There is an emergency, immediately press the "emergency stop" button or pull down the air switch;

4. Pay attention to the grinding of glass drilling machines at any time: Moving wheel loss should be

compensated in time;

5. Keep the water tank has sufficient cooling water at any time and clean water quality to avoid burning

grinding wheels and glass, and timely clean up the grinding impurities of entering and exiting the

water pipeline, keeping the water circuit unobstructed;

6. Check out whether all glass drilling machine travel switching work and whether the control direction

is correct before work.

7. Do a good job of personnel protection, bring goggles and anti -cutting gloves.It is forbidden to

wear shoes and clothes with naked skin to prevent cutting.

Operation process

1. Before the start of each shift, you should first inject lubricating oil into each oil injection site of the

establishment of the glass drilling machine and check the tightening of the belt. Observe whether

there is a foreign body or the glass on the machine correctly.No abnormality, whether the drill is worn,

and after everything is normal, you can start working;

2. Connect the power to test whether the machine runs well;

3. If there is a water spray and cooling function, open the water spray treatment function first;

4. When drilling glass, the drilling bits under the vertical glass drilling machine are easy to squeeze the

glass, so when drilling the glass, the pressure must be very low when the pressure can be adjusted.You

can upgrade to about 0.46MPa;

5. The core material in the seasoning drawer should be cleaned in time, otherwise the core pile of the

material will be stuck in the jellyr.Especially when drilling diameter is greater than 100mmj, a few holes

of each drill should be cleaned once;

6. When cleaning the vertical glass drilling movement, the seasoning device should be in the unloading

position so that the seasoning drawer can be pulled out smoothly.It is in the seasoning position, which

can easily clean the feed core;

7. During the drilling process, pay attention to observe whether there are abnormalities. If an abnormal

phenomenon occurs, press the emergency stop button in time and deal with it in time;

8. After the drilling is completed, clean up each component of the drilling machine to prevent leftover

glass residues.

Finally: I hope everyone must follow safety matters and operating processes when drilling glass. On the

one hand, for the quality and machine of the product