DSM20/22/24 L-type High Speed Double Edger Line

Brand GTM

Product origin CHINA

Delivery time 60 Days

Supply capacity 10sets/month

Certified By CE, SGS

15m/min High-speed double edger line, four sides bottom and arrises of glass can be processed at one time by rough, fine grinding, and pneumatic polishing.

DSM20/22/22 High-Speed Double Edger Line

DSM20/22/24 Series High-speed double edger line configuration:

No. | Commodity | Model | Unit | Quantity | Remark |

1 | Automatic detecting table | DJC4225 | Set | 1 | Automatic detecting,Min. Processing Size:380*380mm |

2 | 1# High speed double edger | DSM2242 | Set | 1 | 22 Spindles,High Speed,4.2 miters ,Min. Size:350*350mm |

3 | Automatic Transfer Table | DZT4225 | Set | 1 | Automatic transfer |

4 | 2# High speed double edger | DSM2225 | Set | 1 | 22 Spindles,High Speed,2.5 miters ,Min. Size:350*350mm |

General Description:

1. DSM20/22/24 High-speed double edger line, four sides bottom and arrises of glass can be processed at one time by rough, fine grinding, and pneumatic polishing.

2. High-speed double edger line is specially used for processing flat glass. It is suitable for the deep processing of glass in construction, engineering, furniture, and other industries.

3. High-speed double edging production line is equipped with the automatic detecting table, the machine automatically opens and closes, fast adjustment, without manual input, greatly improve the efficiency and capacity of production.

4. Precision: Width adjustment adopts servo motor control, precision screw structure;

5. High speed: opening and closing speed up to 8 m/min, glass conveying speed 1-15 m/min;

6. Production capacity: 2.5 times of the traditional double edger, the processing efficiency is significantly improved;

7. Automation: It can be connected with glass cutting line, washing machine, and other equipment into automatic production line;

Technical Parameter:

3.1. Max.processing glass width :4200mm*2500mm

3.2. Min. processing glass size: 350*350mm

3.3. Processing glass thickness: 3~25mm

3.4.Processing speed: 1~15M/min

3.5. Total power: 100KW

Wheels Disposal:

(From input to output end) ←

Spindles | No.11 | No.10 | No.9 | No.8 | No.7 | No.6 | NO.5 | No.4 | No.3 | No.2 | No.1 |

Motors | 1.5KW 1400rpm | 1.5KW 1395rpm | 2.2KW 3200rpm | 2.2KW 3200rpm | 2.2KW 2840rpm | 2.2KW 2840rpm | 2.2KW 2840rpm | 2.2KW 2840rpm | 3KW 4200rpm | 3KW 4200rpm | 3KW 4200rpm |

Wheels | 11#wheel BK40 wheel | 10# CE3 wheel

| 9#wheel 10S60 wheel | 8#wheel 10S40 wheel | 7#wheel Fine grinding BK60 | 6#wheel Resin wheel | 5#wheel Fine grinding BK60 | 4#wheel Resin wheel | 3#wheel Resin wheel | 2#wheel Diamond wheel | 1#wheel Diamond wheel |

Remark | For film removal | No.8~10 spindles For flat edge | No.6~7 spindles for lower 45°arris | No.4~5 spindles for upper 45° arris | No.1~3 spindles for flat edge | ||||||

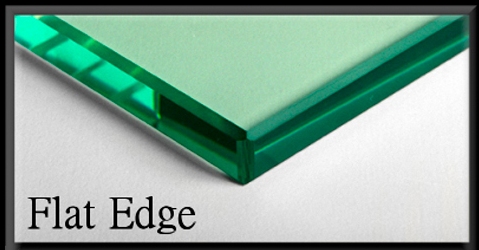

Glass Samples: