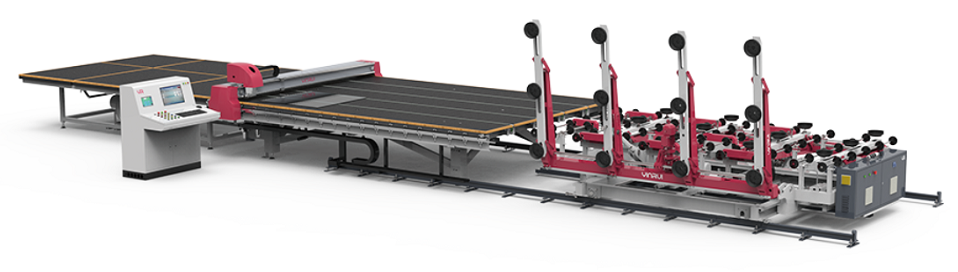

YR-4228 Automatic Standard Glass cutting Line

Brand YINRUI

Product origin CHINA

Delivery time 45days

Supply capacity 20set/month

Certified By CE, SGS

CNC-4228 automatic glass cutting line briefly; GTM Series CNC Full Automatic Glass Cutting Line

■ Composition

This line consists of three parts -- full auto-loading table, full auto glass cutter, and auto glass

breaking unit to realize the flow processes of glass loading, cutting, and breaking.

■ Briefing

This line has been comprehensively upgraded by means of the introduction of European leading

technology, the world's newest tech and process to eliminate insufficient performances, incomplete

functions and unstable operation from domestic glass loader, moreover, through the precise racks,

slide-rails, servo motors, and pneumatic elements, it achieves long-term stable accuracy and

fast running; with the newest American Gail control system, it features even faster operation,

higher safety, higher efficiency, more stability, and better accuracy; with the photoelectric

positioning, it facilitates simple and precise operation and prominent labor savings.

YR-4228 AUTOMATIC Standard GLASS CUTTING LINE

1.设备简介 Equipment introduction

Its working principle is to transport the glass to the worktable by the conveyor belt. Firstly, the photoelectric positioning will make the position right, and the glass will be cut through the cutter head mechanism. The control part of the machine adopts CNC motion control, and the driving part uses advanced AC. servo motor.

The air cushion breaking table is a way of air-floating to transfer the cut glass , manually move to a suitable position, using the auxiliary breaking bar to break glass auor directly with the hand to break the glass sheet. The air volume is adjustable and the foot switch is used to control the action of the breaking bar. The device is simple to operate and maintenance-free

For more details please kindly contact with us +8613924551532 (Whatsapp number)