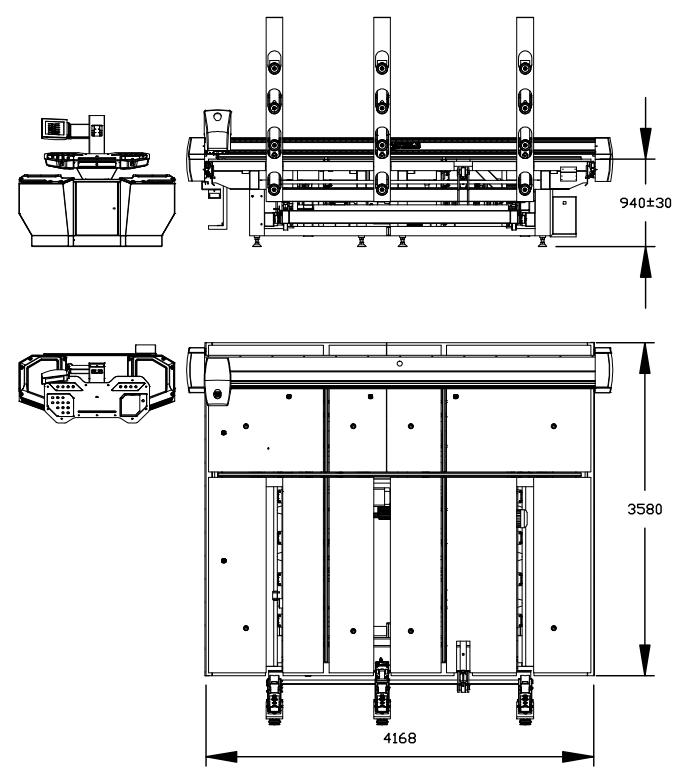

CNC-3826 Automatic CNC glass cutting machine (all in one)

Brand YINRUI

Product origin CHINA

Delivery time 60days

Supply capacity 30

Certified By CE, SGS

This machine set auto loading, auto cutting, and auto breaking in one table.

Its max cutting speed can be 180M/min

The daily capacity is 800-1500M2

The cutting precision is 0.25mm/m

The loading glass time is 15s-30s per piece

It can walk in 360 degree by controlling panel. CNC controlling system

YR-AD3728 Multifunctional Full-auto CNC glass cutting machine (all in one)

I.SPECIAL MANUFACTURE

★High strength quenched steel frame: the superior steel was put outdoors for six months to eliminating stress and used annealing process to eliminate residual stress, to ensure the frame no-deformation. Steel thickness reaches 6 mm which guarantee its steady in any environment and any temperature.

★Grinding level rack technology:High-quality grinding level rack is installed on both sides of glass cutting machine to make sure running high rigidity and precision.

★The cutting bridge using aerospace al-mg alloy integrate casting molding, After use high precision CNC working center processing, sturdy & light. All kinds of precision error caused by vibration or weld cracking will not occur in a long-term continuous production. The cutting speed reach staggering 180 m/min, the acceleration is 6 m/s².

★Dual drivers : Based on the single-drive cutting bridge technology innovation. we have developedan exclusive dual-drive technology to improve the cutting bridge stability and processing synchronization

and automatically forming drawings and cutting directly.

3.Air cylinder cutting technology: Cutting tool bit is controlled by Output pressure and mechatronic type of

4.Drilling positioning function: shape data have drill positioning function. It can fix the drilling holes position

5.On-line typesetting and optimization function: Including optimization software, which can combined sort any